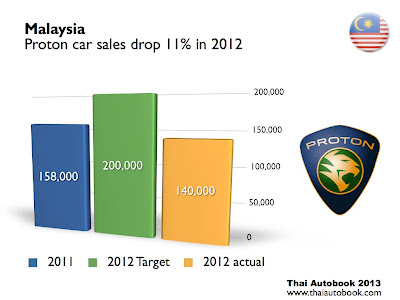

Automotive sector to drive Malaysia's competitiveness

VIA BUSINESS TIMES : THE automotive sector's transformation map has and will continue to make Malaysia competitive, even with challenging free trade pacts like the Trans-Pacific Partnership (TPP), which Malaysia hopes to be a member. Signs of steady improvement in the sector have been showing in the past decade since the Asean Free Trade Area (Afta), Japan-Malaysia Economic Partnership Agreement and the Malaysia-Australia Free Trade Agreement (FTA), enabling Malaysia to be on the same page as the leading automotive countries in the world. "(Global) competitiveness is what we have been preparing for. Right from Afta, the government has been liberalising the industry," said Malaysia Automotive Institute chief executive officer Madani Sahari. With Afta, for instance, there is nothing to stop automotive manufacturers from using Indonesia to sell their vehicles to the Malaysian market. Both the trade pacts with Japan and Australia, which come into effect in 2016, will see zero